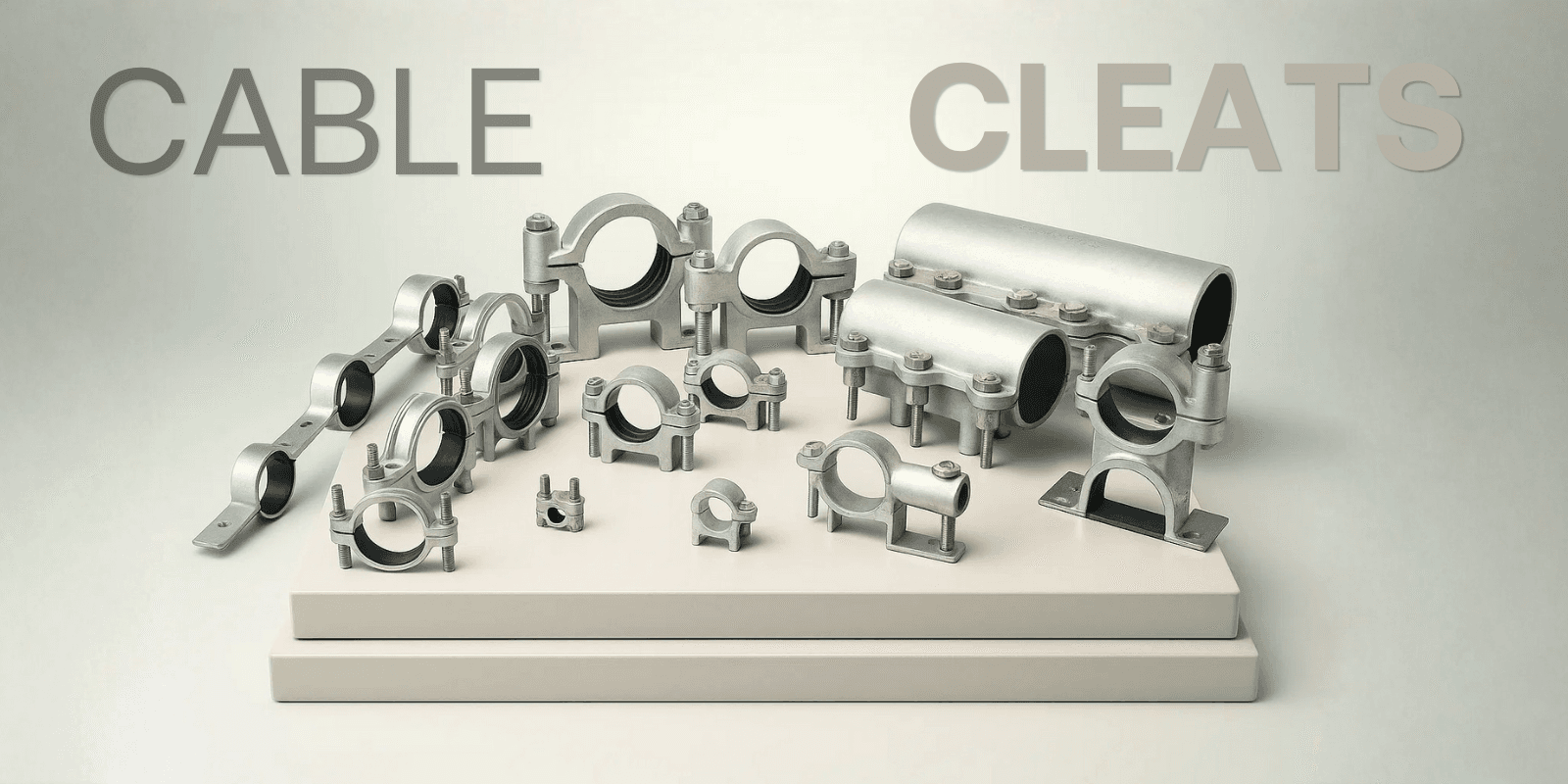

Cable cleats are essential components in electrical installations, providing mechanical retention, spacing, and support for power cables. They prevent damage caused by movement, vibration, or the high electromechanical forces that occur during short-circuit faults.

Peace Power cable cleats ensure that cables remain securely fixed, reducing mechanical stress on the cable and its terminations while maintaining system integrity and safety.

By providing the correct level of restraint, cable cleats safeguard personnel, protect equipment, and enhance the long-term reliability of power systems.

Peace Power cable cleats are designed and certified in accordance with IEC 61914, which defines performance and testing methods for cleats and intermediate restraints.

In compliance with BS 7671:2008 (IET Wiring Regulations):

Peace Power cleats ensure compliance with these standards and align with Zero Harm and HSE policies.

Circuit breakers provide electrical protection, but they do not prevent mechanical damage to cables during faults. When a short-circuit occurs, powerful magnetic forces act within the first 5 milliseconds—well before a breaker can trip.

Without cable cleats, cables can whip violently, damaging insulation, supports, and terminations. Properly rated Peace Power cleats restrain cables during this critical fault period, preserving system integrity and reducing downtime.

Every Peace Power cleat is precision-engineered and tested to ensure reliable, safe, and standards-compliant installation.

Used for single-core cables arranged in trefoil formation to minimize magnetic fields and interference in three-phase systems.

Designed for securing individual cables to trays, ladders, or channels. Quick to install and UV/corrosion resistant.

Used for cables containing multiple conductors within one sheath. Provide organized, vibration-resistant support.

Installed between primary cleats to prevent cable sag and enhance mechanical stability over long runs.

| Material Type | Description | Typical Use |

|---|---|---|

| Aluminium Alloy | Lightweight, corrosion-resistant, ideal for HV systems | Substations, Power Plants |

| Stainless Steel (304/316) | High strength and chemical resistance | Industrial, Marine, Offshore |

| Glass-Reinforced Nylon | Non-conductive, flame-retardant, UV-stabilized | Indoor LV/MV installations |

| Composite Hybrid | Combines metal strength with polymer insulation | Dielectric isolation + high load-bearing |

Peace Power offers expert support for cleat selection based on cable size, spacing, system fault level, and environmental conditions.

Our design team ensures every installation meets IEC 61914 and BS 7671 standards.

Engineered Precision. Proven Protection. Trusted Worldwide.

In power transmission and distribution networks, single core power cables are often installed individually rather than as part of a multicore assembly. When mounted in parallel formations on trays, ladders, or support structures, each conductor generates its own electromagnetic field proportional to the current it carries. Under normal operating conditions, these fields remain steady and well balanced.

However, during a three-phase short-circuit event, the fault current rises sharply, producing extremely high electrodynamic forces between the single core cables. These forces can cause violent cable movement if not mechanically restrained, potentially leading to severe damage or safety hazards.

To control this movement, single cable cleats are installed at engineered intervals along the cable route. These cleats securely hold each cable in position and ensure that the conductor remains fixed relative to adjacent cables and the supporting structure — both during normal operation and under extreme fault conditions.

When fault current flows through the cables, large electromagnetic forces develop due to interaction between the cable conductors. The behaviour of the cables under short-circuit conditions typically includes:

These forces can reach several kilonewtons per metre, depending on cable size, spacing, and system fault level. Without proper restraint, uncontrolled cable movement may result in:

Correct selection and installation of single cable cleats is essential to ensure that the cable system can withstand both peak (dynamic) and RMS (thermal) short-circuit forces. The cleats must provide enough mechanical strength to prevent displacement during the fault while avoiding damage to the cable sheath under high compression loads.

As every system uses different combinations of:

The mechanical response during a fault varies significantly. In theory, an unlimited number of test conditions would be required to characterise every possible installation scenario.

The Peace Power Single Omega Aluminium Cable Cleats are independently tested for Short Circuit Withstand capability in accordance with IEC 61914:2021.

The cleats have been successfully tested for a short-circuit current level of 50 kA for 1 second, ensuring reliable mechanical restraint and secure cable retention under extreme fault conditions.

This high-performance short-circuit rating confirms that Peace Power Omega Cleats provide enhanced safety and protection for power distribution systems, substations, industrial plants, renewable energy installations, and utility networks.

In emergency situations such as building or industrial fires, electrical circuits that power life-safety systems must remain secure and operational for as long as possible. Even when cables are fire-resistant by design, their performance can be compromised if the mechanical restraint system fails under heat, load or structural stress.

Peace Power Aluminium Cable Cleats are engineered to provide reliable mechanical support in installations where cables may be exposed to high temperatures and emergency operating conditions. Their rigid metallic construction ensures cable stability and alignment, reducing the risk of cable collapse, short-circuit contact, or uncontrolled movement caused by thermal expansion.

The properties of aluminium alloy provide natural thermal endurance, enabling the cleats to retain structural performance in elevated-temperature environments typically associated with fire scenarios.

During fire conditions, electrical systems supporting emergency and evacuation operations depend on two critical capabilities:

When cable insulation softens or internal conductors expand, the cleat prevents movement, sagging, or collision with adjacent circuits or metalwork. This is essential for maintaining circuit integrity and functional continuity.

Peace Power aluminium cleats contribute to supporting critical monitoring and automation infrastructure.

Peace Power cleats are designed not simply for normal operating environments, but for critical situations where failure cannot be tolerated. Their engineered aluminium structure enhances the performance of fire-rated cables, helping safeguard people, infrastructure and continuous operation during real-world emergency conditions.